Sign up for our newsletter to receive updates about new articles, great deals, and information about the activities you love and the gear that makes them possible:

Have You Read Our Other Content?

A Wilderness of the People – The 2023 Boundary Waters Canoe Area Wilderness Situational Assessment

The June 28th USFS newsletter contained the results of a six-month-long survey with confidential feedback from 100 individuals representing a wide scope of BWCAW users, affiliated businesses, nonprofits, and managing agencies. Their survey delved deep into the complexities of managing America’s busiest, and often one of the most complicated and controversial, wilderness areas. The results…

10 Steps in Planning an October Canoe Trip to the BWCA

Fall is a magical season in canoe country: a brief respite of quiet calm between the relative chaos of summer and the icy grip of winter. And, in many ways, the experience of a canoe trip in the BWCA is greatly enriched by the season. Once October 1st rolls around though, the looming threat of…

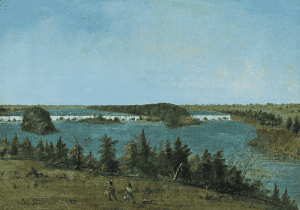

Footsteps of the Past – Tracing Minnesota’s Historic Portages

. In 1992, a report was concluded as portages of historical significance were surveyed in order to be included in a bid for the National Register of Historic Places. As part of this survey, archeologists looked for signs of the past and recorded the conditions of the trails and how time had changed them. The results were varied. Some trails had vanished completely or become so overgrown that they were nearly impossible to follow. In a few places in Minnesota though, there are still opportunities to trod in the tread of voyageurs and native peoples alike with a canoe on your shoulders and a sense of adventure in your heart. The spirit of the portage is still very much alive in the land of 10,000 lakes. Here are some of the most historic portages in the state.

The Ten Most Challenging BWCA Lakes to Visit

The Boundary Water Canoe Area Wilderness encompasses over a million acres and 1100 named lakes interconnected by portages and streams, but sometimes that vast expanse can feel a little cramped, especially along entries where larger numbers of groups congregate. For the cynic who feels the BWCA is lacking some inherent quality of wilderness in this…

The Best Month To Plan A Canoe Trip? Might Be September…

For most of us, the best time to go on a canoe trip is any and every opportunity presented. But if you have a little flexibility in planning your trip, September is a wonderful month to visit canoe country. Here are a few reasons why September might be the best month to plan a wilderness canoe…

Map Mondays – Week 4 – Bower Trout to Little Indian Sioux North

As part of our continuing series on the “route planning game,” we are creating routes using randomly selected entry points, exit points, and number of days to create unique and fun BWCA routes. This week’s randomly selected entry points set us up for a cross-BWCA trip. It’s a long, 10-night trip that covers most of…

Smoke On the Horizon – How Fire Towers Changed BWCA History

A drive out from Ely today, and you won’t see many fire towers. They’ve vanished as antiquated methods of dutiful rangers past. But less people remember how those fire towers have shaped our wilderness experiences.

How Trees Tell the Story of the BWCA

Today is the International Day of Forests which means it’s the perfect day to celebrate the trees of the BWCA. The Boundary Waters are a unique mosaic of forests born out of wildfire, windstorms, logging, and the passage of time. Despite the history of disturbance, the Boundary Waters contain the largest tracts of old growth…

Is it Spring in Canoe Country Yet?

This winter has felt like a long one. The final weeks before opening water always do, but this year has felt extra drawn out. Numerous cities in Minnesota have broken their snowfall records and ice is still firmly on the lakes around Ely. To the Boundary Waters enthusiast, this is a painful time of year…